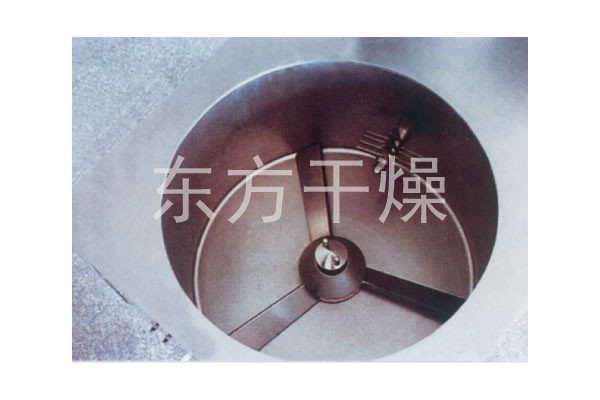

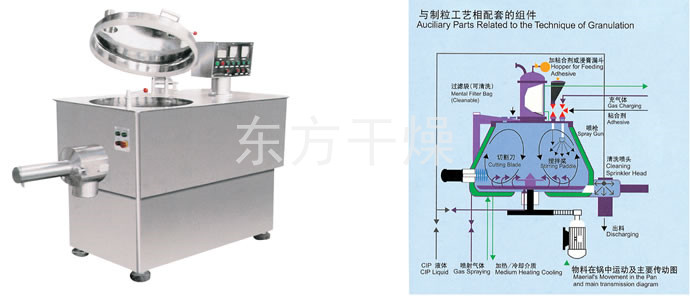

working principle

Powder material with a binder in a cylindrical vessel from the bottom of the slurry was mixed thoroughly mixed into the moist soft material and then cut by the side of the high-speed smash paddle uniformly wet granules.

Features

◎ The machine adopts horizontal cylinder structure, reasonable structure.

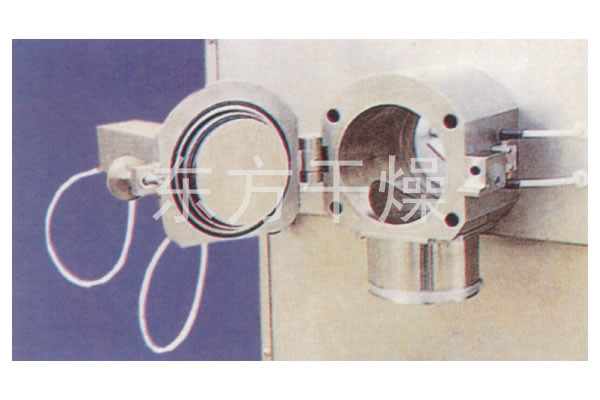

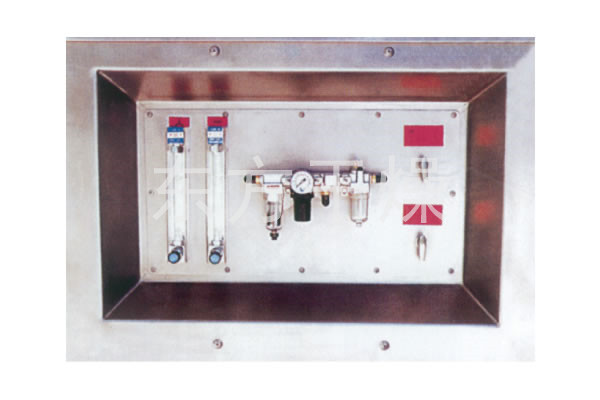

◎ pneumatic sealing drive shaft, cleaning can be switched to water.

◎ fluidized granulation, into spherical particles, good liquidity.

◎ 25% less than conventional technology adhesives, drying time is shortened.

◎ dry mixed batch only 2 minutes, granulation 1-4 minutes, 4-5 times to improve efficiency than the traditional process.

◎ completed within the same closed container, dry mix - wet mixing - granulating, process shortened.

◎ whole operation has strict security measures.

◎ dips can be made according to user requirements.

Technical Specifications

| Specifications | A | B | C×D | E | F |

| 50 | 320 | 950 | 1250×800 | 970 | 1650 |

| 150 | 420 | 1000 | 1350×800 | 1050 | 1750 |

| 200 | 500 | 1100 | 1650×940 | 1450 | 2050 |

| 250 | 500 | 1160 | 1650×940 | 1400 | 2260 |

| 300 | 550 | 1200 | 1700×1000 | 1400 | 2310 |

| 400 | 670 | 1300 | 1860×1100 | 1550 | 2410 |

| 600 | 750 | 1500 | 2000×1230 | 1750 | 2610 |

| Name | Model | ||||||

| 50 | 150 | 200 | 250 | 300 | 400 | 600 | |

| Volume L | 50 | 150 | 200 | 250 | 300 | 400 | 600 |

| Yield kg/batch | 15 | 50 | 80 | 100 | 130 | 200 | 280 |

| Mixing speed r.p.m | 200/400 | 180/270 | 180/270 | 180/270 | 140/220 | 106/155 | 80/120 |

| Hybrid power kw | 4/5.5 | 6.5/8 | 9/11 | 9/11 | 13/16 | 18.5/22 | 22/30 |

| Cutting speed r.p.m | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 |

| Cutting power kw | 1.3/1.8 | 2.4/3 | 4.5/5.5 | 4.5/5.5 | 4.5/5.5 | 6.5/8 | 9/11 |

| Compressed air consumption m3/min | 0.6 | 0.9 | 0.9 | 0.9 | 1.1 | 1.5 | 1.8 |

| Weight kg | 500 | 800 | 1000 | 1300 | 1800 | 2200 | 2600 |