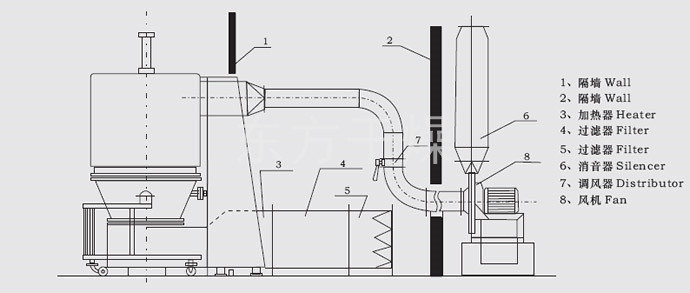

Working principle

After the air is purified and heated, introduced from the bottom induced draft fan through the hole hopper screen. In the studio, by mixing and fluidization negative pressure is formed, after the water is evaporated and removed rapidly, fast drying material.

Features

◎ fluidized bed is round structure to avoid dead ends.

◎ the hopper stirring to avoid agglomeration of raw material and forming canal of flow when dry.

◎ The turn dump Reap prompt and thorough, can also be designed as request access to material systems.

◎ Seal negative pressure operation, airflow through the filter. Easy to operate, easy to clean.

◎ drying speed, temperature symmetry, each batch of drying time is generally 20-30 minutes, depending on the material may be.

Adapt materials

◎ Mechanism screw extrusion particles, rock particles, high speed mixing wet granules.

◎ medicine, food, feed, chemical and other fields wet granules dried and powdered materials.

◎ large particles, small block, sticky block granular materials.

◎ dry volume change material konjac.

Technical Specifications

| Project | Model | ||||||

| Feeding(kg) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Fan power(kw) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 45 |

| Mixing power(kw) | 0.55 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | 2.2 |

| Stirring speed(rpm) | 8~11 | ||||||

| Steam consumption(kg/h) | 141 | 170 | 170 | 240 | 282 | 366 | 451 |

| Operating time(min) | 15-30(Based on material properties revised) | ||||||

| Host height | 2700 | 2900 | 2900 | 2900 | 2900 | 3300 | 3500 |